Every business that depends on machines or equipment knows how stressful it can be when something stops working. A single failure can delay jobs, upset customers, and cost more money than expected. Many service companies live in that constant rush, reacting to problems instead of staying ahead of them.

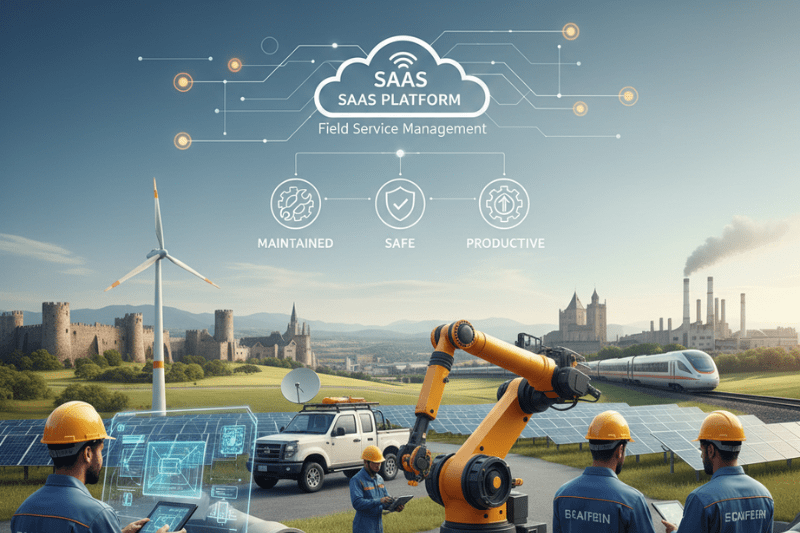

That is where CMMS software comes in. CMMS stands for Computerized Maintenance Management System. The name might sound technical, but it simply means a digital tool that helps organize, plan, and track all maintenance work in one place.

Instead of relying on paper, calls, or memory, everything is stored in one system that anyone on the team can access when needed.

What CMMS Really Does

A CMMS is like a digital workspace where all maintenance activity lives. Every asset, from a vehicle to a machine, has its own record. You can see when it was installed, when it was last serviced, and what problems it has had.

It helps managers plan work before equipment breaks down. It shows technicians exactly what to do and stores every repair and inspection in one place. The goal is simple: no surprises, no missing information, and no more reactive maintenance.

Before CMMS existed, many companies only acted when something failed. This kind of reactive maintenance causes downtime and wastes money. With CMMS, maintenance becomes preventive and organized. Small issues are fixed before they turn into big ones.

Why It Matters

CMMS brings structure where there used to be confusion. It keeps people connected and informed. Managers can see what is happening without making calls or chasing updates. Technicians know their next job, what tools they need, and what steps to follow.

Without CMMS, every person works in their own way. One technician may have notes in a notebook, another may rely on memory. It works for a while, but as the business grows, things start falling through the cracks. Missed jobs, repeated repairs, and unhappy customers become the norm.

A CMMS fixes this by making work visible and traceable. You can open the system and see what was done, who did it, and what it cost. It is like having your whole maintenance history in your pocket.

How It Helps Every Day

The benefits of CMMS go far beyond keeping things organized. It reduces downtime because equipment gets serviced on time. It saves money because you plan ahead instead of paying for emergency repairs.

It also makes technicians more confident. They no longer waste time looking for information or instructions. Everything they need is on their mobile device. For customers, it means better service, faster response, and more consistent results.

Another big advantage is compliance. Many industries have strict rules for safety and inspections. CMMS keeps full records of every job, so when it is time for an audit, everything is already documented and easy to show.

Over time, a good CMMS becomes the foundation of reliable operations.

What Happens Without It

Without CMMS, a company runs in constant reaction mode. Repairs happen only when something breaks. Data is scattered in files or stored in people’s heads. Spare parts run out unexpectedly. Managers cannot see where time or money is going.

Training new technicians also becomes difficult because there is no clear record of how things should be done. When experienced staff leave, their knowledge leaves with them.

This way of working is not sustainable. CMMS brings calm to the chaos and gives structure to the everyday routine.

How Wello Solutions Fits In

There are many CMMS systems available, but Wello Solutions was designed specifically for service companies that need more than maintenance tracking. It combines job scheduling, asset management, customer management, and reporting in one simple and clear system.

Wello helps teams plan preventive maintenance, manage spare parts, follow digital checklists, and send reports automatically. Technicians use it on their phones to see their tasks, log parts used, take photos, and collect customer approval.

Managers can see every job live on their dashboards. They know what is completed, what is delayed, and where costs are coming from. This gives them a clear view of the business without waiting for updates.

The platform connects easily with accounting software, ERPs, and other tools through integrations like Zapier and Make.com. This keeps data accurate and removes the need to enter the same information twice.

Wello Solutions does not just organize work. It builds confidence and consistency for managers, technicians, and customers alike.

A Simple Example

A company that manages HVAC maintenance for commercial buildings used to rely on spreadsheets and phone calls. Work orders were mixed up, spare parts went missing, and invoices were often delayed. Customers complained about slow communication.

When they switched to Wello Solutions, every service job became part of a clear digital workflow. The system reminded them when preventive maintenance was due. Technicians followed mobile checklists and uploaded reports from the job site. Managers saw updates in real time.

Downtime dropped, customer satisfaction increased, and the company began winning new contracts because it became known for reliability. It was not just about using software. It was about building a better structure and keeping promises.

The Road Ahead

CMMS keeps evolving with technology. Automation and connected devices will make maintenance smarter in the future. Machines will report their own condition when something starts to wear out. The system will create a work order automatically, check stock levels, and suggest the right technician for the job.

Wello Solutions is already prepared for this future. It grows with businesses and adapts to smarter ways of working.