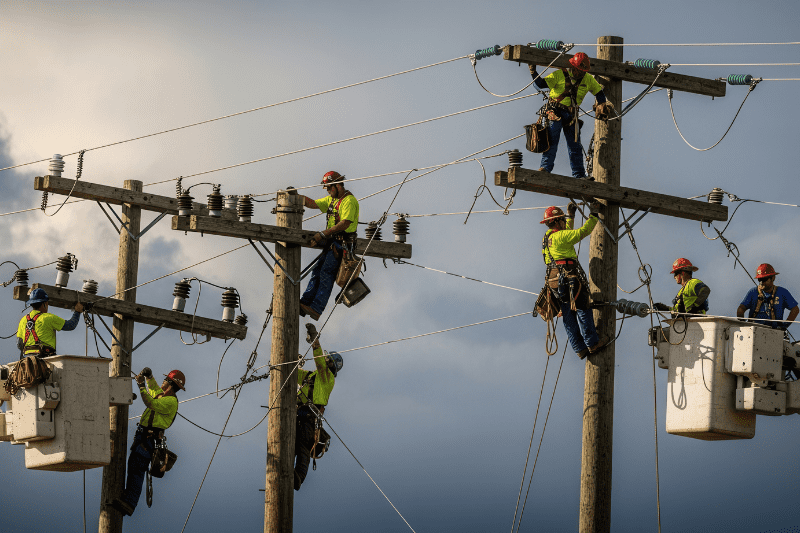

Utility companies work in one of the most demanding environments in the world. Their networks are long, their assets are exposed to harsh conditions, and their work spans electrical systems, water networks, gas infrastructure, district heating, renewable generation, sensors, controls, and customer connections. Every service interruption becomes visible to thousands of people. Every maintenance delay has financial and regulatory consequences. Every inspection or repair adds to an enormous flow of daily work that must be planned, executed, and documented with accuracy.

The only way to keep this entire system reliable is through strong utility asset management. Yet many utilities still struggle to manage assets in a structured and predictable way. The problems do not come from lack of skill or lack of effort. The problems come from old tools, scattered information, incomplete histories, and work processes that were never designed for the level of complexity utilities now face.

Modern Field Service Management software, often referred to as FSM, is becoming the missing link that helps utilities finally bring order, clarity, and consistency to the way they plan, track, and maintain their assets. Wello Solutions plays a major role here because its design is built around technicians, dispatchers, planners, and engineers who must keep the network running. Instead of acting as a heavy enterprise system, Wello offers a practical and simple structure that fits directly into field operations. It gives utilities a reliable way to maintain asset records, improve visibility, organise maintenance work, and capture evidence with clarity.

This article explains the major challenges utilities face in asset management and how modern FSM, supported by Wello Solutions, helps solve them in daily operations.

The challenge of disconnected and outdated asset information

Many utility companies still work with asset records that live in several different places. Some departments rely on GIS to understand where assets are located. Others keep essential details inside spreadsheets. Older inspection records live as PDFs that nobody can search properly. Field notes exist in notebooks or in personal files that never enter the official system. New smart sensors and IoT devices are installed faster than back office systems can be updated.

This lack of a single, trusted asset view creates long term problems. Planning teams may think a site contains one configuration but the technician finds another. Work Orders might refer to asset IDs that no longer match what exists in the field. A pole that was replaced years ago still appears active in the system. A transformer that was upgraded may still show its old rating. A new meter installed last week is not yet visible to the dispatch team.

Modern FSM tools solve a large part of this problem because they connect the office view with the field view. Wello Solutions provides each asset with a clear profile that grows over time. Photos, inspection history, technician notes, and maintenance results are stored in one structured timeline. When a technician arrives at a site and notices a mismatch, they can update the information instantly inside the mobile app. The update is saved, time stamped, and visible to planners and engineers.

Over time, this natural correction cycle builds a much more accurate and trustworthy asset register. There is no need for a full national survey to clean up data. The data improves each time a technician visits and records the real situation on site.

The problem of reactive maintenance and surprise failures

Utility networks depend on stable equipment. When a pump fails inside a water treatment plant, the entire flow may stop. When a transformer overheats, the grid loses stability. When corrosion appears, outages spread quickly. Many utilities still respond to these failures only after they occur. This reactive cycle creates stress, high repair costs, emergency labour, and customer dissatisfaction.

Some utilities already follow fixed schedules for preventive maintenance, but these schedules are often based on time, not condition. A transformer may receive a check every six months even though it is healthy. Another asset may fail between inspections because it deteriorated faster than expected.

Utilities can break this reactive pattern by creating better visibility into actual asset condition. Wello Solutions helps this process by providing structured inspection forms that technicians complete directly in the field. Instead of paper checklists, every reading becomes searchable data. Photos show deterioration. Notes describe unusual behaviour. Patterns become visible because every inspection and every repair attaches to the same digital history.

This gives engineers and planners early warning signs. They can see which assets repeatedly appear in corrective jobs. They can see where heat marks, leaks, unusual vibration, or cable wear become more frequent. Even without advanced predictive analytics, utilities can shift from sudden failures to controlled interventions. The field data collected through Wello becomes the foundation for smarter planning and fewer emergencies.

The struggle with capital planning and unclear priorities

Utilities face the ongoing challenge of deciding which assets need replacement first. Budget constraints require careful choices. Old networks have growing risks. New loads from electric vehicles and renewable generation stress the grid further. Everything seems urgent. Without a clear method of prioritisation, the wrong assets get upgraded while high risk assets continue to deteriorate.

True capital planning requires knowing an asset’s condition, understanding its importance and seeing the long term cost of keeping it alive versus replacing it. Much of this insight comes from the field. Small issues recorded during routine inspections create a reliable picture of asset behaviour. Repeated repairs point to assets that near the end of their useful life.

Wello supports this through its equipment timeline that shows every event linked to an asset. Engineers can open an asset and instantly see all past issues, photos from multiple years, the frequency of repairs and the materials used. This level of visibility helps utilities defend capital decisions. If a regulator or internal auditor asks why a replacement is necessary, Wello provides clear evidence. It becomes easy to show the number of faults, the safety risks, and the actual condition.

Capital teams do not need to rely on guesswork. They have data directly from the field that supports their plans.

Heavy compliance responsibilities and documentation gaps

Utilities operate in a highly regulated environment. Inspections must follow specific rules. Maintenance must be documented clearly. Safety checks must be recorded. Environmental impacts must be monitored. Auditors must be able to see proof of work at any moment.

Many utilities still store this evidence in scattered folders. Photos sit in random drives. Paper forms end up in filing cabinets. Information is missing or not linked to the correct asset. When an audit approaches, teams spend days searching for the required documentation.

Modern FSM software solves this problem by embedding documentation into the workflow itself. When a technician completes a job inside Wello, they must fill in the required forms, capture photos, log measurements, and submit a final summary. All data is automatically time stamped and linked to the correct asset and Work Order.

This builds a perfect audit trail. Compliance teams can open a site record and see everything that happened across the year. They can verify inspection frequency, check the condition of assets, and confirm when repairs were completed. Preparing for audits becomes simpler because all documentation is already organised and complete.

The communication gap between field and office teams

Utility operations depend on constant communication. Planners need to know what is happening in the field. Engineers need accurate reports to adjust maintenance plans. Dispatchers need real time updates to balance urgent and scheduled work. Technicians need clear instructions, the latest maps, and correct asset information.

When this communication is delayed or inconsistent, mistakes follow quickly. A technician may repair the wrong asset if labels are outdated. A completed inspection may never reach the office if paperwork is lost. A safety condition might be identified in the field but not acted upon in time because the message does not reach the right team.

Wello closes this communication gap through real time connections between the field and the office. Planners create Work Orders with all required details. Technicians receive the tasks instantly in the mobile app. As they progress, they update the status, record results, and add photos. The office sees this immediately. Nothing depends on phone calls or end of day reports.

This real time visibility improves asset accuracy and reduces risk. If a technician discovers missing grounding, corrosion, a damaged pole number, or a dangerous condition, they can document it instantly and alert the office. The information becomes part of the asset record, not a note that disappears.

Misalignment between GIS, asset records, and work systems

Most utilities already have GIS maps. Many have asset registers. Others use work management platforms. However, these systems do not always communicate smoothly. The GIS may show one layout. The asset register may show different IDs. The work order system may show outdated information.

This misalignment slows down operations. Crews may drive to incorrect locations. Work Orders may be assigned to assets that do not exist. Engineers may rely on maps that do not reflect recent changes.

FSM acts as the operational layer that brings these systems together. Wello integrates with GIS and asset registers so that Work Orders always refer to the correct assets and the correct coordinates. When technicians update asset information in Wello, the corrected data can be synced back to other systems. Over time, this keeps all systems aligned with real world conditions.

The field becomes the source of truth, recorded in consistent and structured ways.

Poor lifecycle tracking and missing retirement records

A utility asset does not only matter on the day it is repaired or inspected. Its full lifecycle matters. Utilities must know when the asset was installed, when it was upgraded, when faults appeared, how many times it was repaired, and when it was removed. Without correct lifecycle tracking, utilities risk maintaining assets that should be retired or mistakenly retiring assets that still exist.

Wello Solutions builds this lifecycle picture automatically. Every Work Order contributes to the asset timeline. Installation creates the first entry. Inspections add condition data. Repairs add evidence and notes. Final retirement is recorded clearly in the same timeline. Once retired, the asset is marked accordingly and no longer appears in active workflows.

This prevents the common problem of ghost assets. It also supports financial planning, since capital teams can calculate depreciation based on real and complete histories instead of assumptions.

The human challenge of overloaded planners and technicians

Asset management is not only about technology. It is also about people. Planners must organise hundreds of jobs while balancing urgent repairs and scheduled maintenance. Technicians must work in difficult conditions, often outdoors, with pressure to restore power or service quickly. When tools are confusing or data is missing, the burden becomes heavier and mistakes become more likely.

FSM must support people, not overwhelm them. Wello is designed with a technician first approach. The mobile app displays tasks in a clean and simple way. Instructions are easy to read. Forms are structured but not complicated. Photo capture is quick. Technicians do not waste time searching for what to do next.

Planners also gain clarity. The Wello planning board shows all jobs, technician availability, and regional assignments in one view. Reassigning work is quick. Balancing urgent calls with ongoing asset maintenance becomes manageable.

When people work with clear tools, the quality of asset data improves naturally. Technicians record more details because the process is simple. Planners update schedules accurately because the interface supports fast decision making. In the end, this human clarity creates stronger asset management.

How modern FSM supports the broader digital roadmap

Utility companies often initiate many digital projects at the same time. They may invest in predictive analytics, network automation, customer portals, or outage management systems. All of these initiatives depend on one foundation: accurate field data and reliable asset history.

Predictive analytics cannot function without correct condition data. Automation cannot work if asset locations are uncertain. Customer reporting cannot be accurate if repair documentation is incomplete. This means FSM plays a central role in every digital transformation. It collects the real world evidence needed for smarter systems to make decisions.

Wello fits naturally into this structure because it captures technician insights, inspection results, asset condition, and operational history in a consistent format. It supports utilities that want to progress step by step. They can begin with Work Order management, then add planned maintenance, then link GIS, then add field inspections, and later integrate condition scoring or predictive models. The platform grows with the organization while remaining simple for daily use.